In the rapidly evolving industrial landscape, maintenance teams are drowning in a sea of disconnected systems. The company’s CMMS holds work order data, the ERP manages inventory, WMS tracks parts movement, and condition monitoring systems generate alerts—all operating in isolation. Sound familiar? It’s a common problem.

After spending over a decade helping companies navigate the complexities of digital asset management, I’ve witnessed firsthand how fragmented maintenance ecosystems cost organizations millions in operational inefficiencies, delayed decision-making, and missed optimization opportunities. However, modern integration platforms like Makini are revolutionizing how industrial companies approach this challenge, enabling seamless connectivity across ERP, CMMS, and WMS systems through a single API. The solution isn’t to replace existing systems—it’s to connect them intelligently.

The Hidden Cost of Digital Silos

Before diving into integration strategies, let’s address the elephant in the room: why do most maintenance departments operate with fragmented systems? The answer is simple—organic growth and vendor lock-in.

Most organizations didn’t wake up one day and decide to implement five different maintenance-related systems. Instead, they evolved organically:

- Started with basic CMMS for work orders

- Added specialized condition monitoring tools

- Integrated ERP for procurement and inventory

- Implemented WMS for warehouse efficiency

- Adopted IoT sensors for real-time monitoring

Each system solved a specific problem but created a new one: data silos. The result? Maintenance planners spending 40% of their time manually transferring data between systems instead of analyzing it for insights.

Building Integration Strategy: A Framework for Success

Creating a connected maintenance ecosystem requires more than just technical implementation—it demands a strategic approach that aligns with operational goals and organizational culture.

Phase 1: Assessment and Mapping

Start by conducting a comprehensive audit of the current maintenance technology stack. Document every system, database, and manual process involved in maintenance operations. Create a data flow map showing how information currently moves (or doesn’t move) between systems.

Key questions to answer:

- Which systems contain critical maintenance data?

- Where are the manual handoffs occurring?

- What data is being duplicated across systems?

- Which processes are causing the most delays?

Phase 2: Prioritizing Integration Points

Not all integrations are created equal. Focus on connections that will deliver the highest impact on key performance indicators. In my experience, these typically include:

High-Impact Integrations:

- CMMS ↔ ERP (for seamless parts procurement and inventory management)

- Condition monitoring ↔ CMMS (for automatic work order generation)

- CMMS ↔ WMS (for real-time parts availability and location tracking)

Medium-Impact Integrations:

- ERP ↔ WMS (for inventory synchronization)

- IoT sensors ↔ Analytics platforms (for predictive insights)

Phase 3: Selecting The Integration Approach

This is where many organizations make critical mistakes. They often choose between building custom integrations in-house or implementing point-to-point connections between vendors. Both approaches have significant drawbacks:

Custom Development Challenges:

- Requires specialized technical expertise

- Time-intensive development and testing

- Ongoing maintenance burden

- Vulnerability to system updates and changes

Point-to-Point Integration Issues:

- Creates a web of dependencies

- Difficult to scale when adding new systems

- Each integration requires separate maintenance

- Limited flexibility for future changes

The Platform-First Approach: A Modern Solution

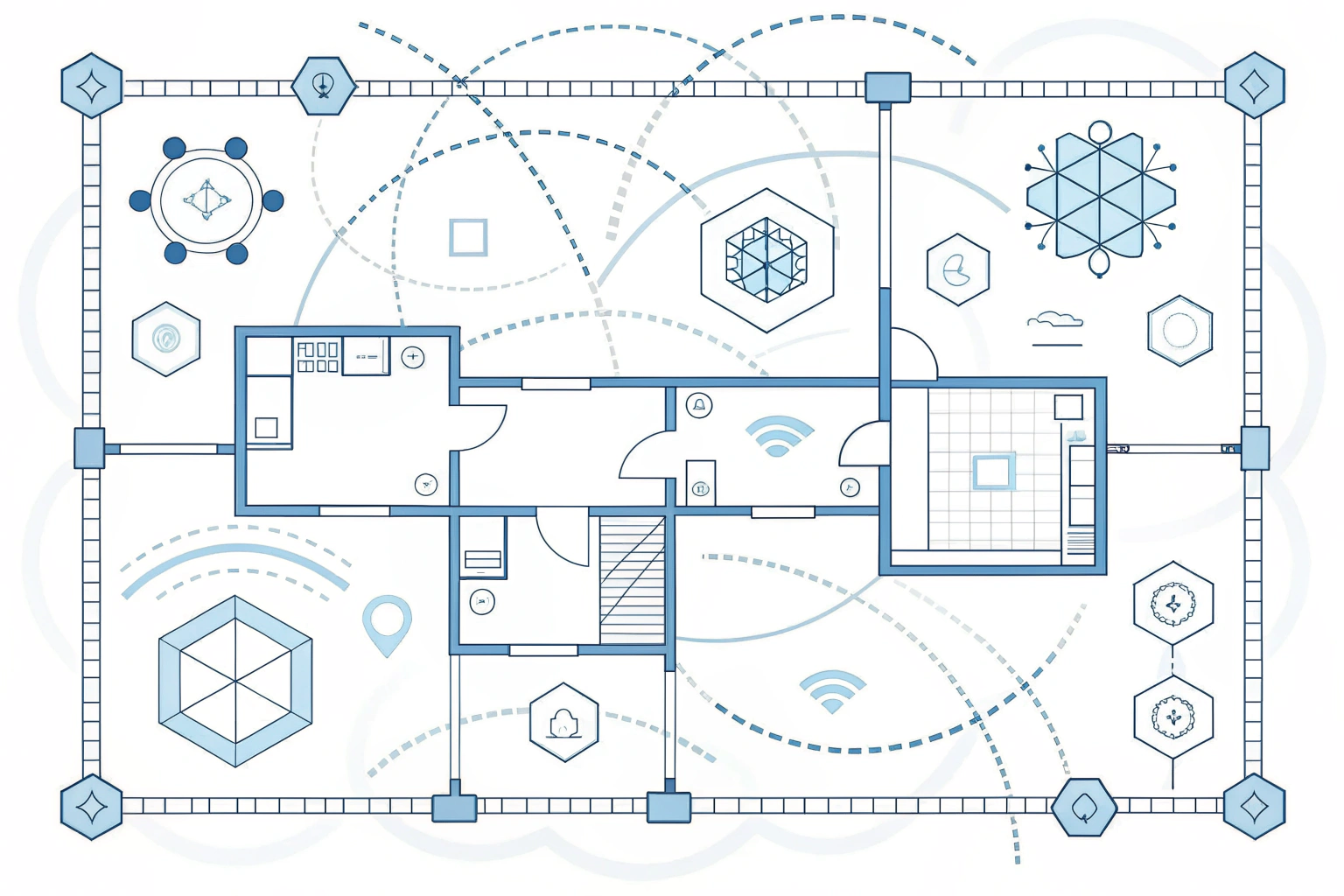

Smart maintenance leaders are adopting a platform-first integration strategy that centralizes connectivity through a unified API layer. Instead of creating individual connections between each system, connect all systems to a central integration platform that manages data flow, transformation, and synchronization.

This approach offers several advantages:

- Scalability: Adding new systems requires only one integration point

- Maintainability: Centralized management of all connections

- Flexibility: Easy to modify data flows without touching individual systems

- Reliability: Built-in error handling and data validation

Companies like Makini have revolutionized this space by providing specialized integration platforms designed specifically for industrial operations. Their unified API approach means connecting CMMS, ERP, and WMS systems in minutes rather than months, with pre-built connectors for hundreds of industrial software systems.

Implementation Roadmap: From Strategy to Reality

Week 1-2: Foundation Setting

- Finalize integration priorities

- Secure stakeholder buy-in and budget approval

- Establish project governance and success metrics

Week 3-4: Technical Setup

- Configure the integration platform

- Establish secure connections to priority systems

- Set up initial data mappings and transformations

Week 5-8: Pilot Implementation

- Start with the highest-impact integration

- Test data flows in a controlled environment

- Train key users on new connected workflows

Week 9-12: Scale and Optimize

- Roll out additional integrations based on priority

- Monitor system performance and data quality

- Gather user feedback and optimize workflows

Measuring Success: KPIs for Connected Maintenance

A well-implemented integration strategy should deliver measurable improvements across multiple dimensions:

Operational Efficiency:

- Reduce manual data entry time by 60-80%

- Decrease work order processing time by 30-50%

- Improve parts availability accuracy to 95%+

Decision-Making Speed:

- Real-time visibility into maintenance operations

- Faster identification of recurring issues

- Predictive insights for preventive maintenance

Cost Management:

- Reduced inventory carrying costs through better synchronization

- Lower emergency procurement expenses

- Decreased system maintenance overhead

Common Pitfalls and How to Avoid Them

Based on my experience consulting with maintenance teams across various industries, here are the most common integration mistakes and how to avoid them:

- Mistake #1: Trying to Integrate Everything at Once

Solution: Start with 2-3 high-impact integrations and build from there. - Mistake #2: Focusing Only on Technical Implementation

Solution: Invest equal effort in change management and user training. - Mistake #3: Ignoring Data Quality Issues

Solution: Clean and standardize data before integration, not after. - Mistake #4: Underestimating Ongoing Maintenance

Solution: Choose integration platforms that minimize maintenance overhead.

The Future of Maintenance Integration

As we look ahead, several trends will shape the evolution of maintenance ecosystems:

AI-Driven Insights: Connected systems will enable more sophisticated predictive analytics and automated decision-making.

Real-Time Optimization: Instant data synchronization will allow for dynamic resource allocation and priority adjustment.

Mobile-First Workflows: Technicians will access and update connected systems seamlessly through mobile interfaces.

Vendor Ecosystem Integration: OEMs and suppliers will integrate directly into maintenance workflows, enabling proactive support and automated parts replenishment.

Taking the First Step

Building a connected maintenance ecosystem might seem daunting, but the key is to start with a clear strategy and the right technology foundation. Focus on solving the most pressing integration challenges first, then build momentum through early wins.

Remember, the goal isn’t perfect integration—it’s meaningful connection that drives better maintenance decisions and improved operational outcomes. Modern platform-based approaches can achieve significant connectivity improvements in weeks, not months.

The question isn’t the need for a connected maintenance ecosystem—it’s how quickly to build one that delivers competitive advantage for the organization.